Before we begin our journey, we must give you a brief history of web offset lithographic printing. First developed in the late 18th century, it is based on the principle that oil and water repel each other. An image of the text is photographically transferred to thin metal, paper, or plastic printing plates. then rollers apply oil- and water-based ink to the plates. Since oil and water do not mix, oil-based ink will not adhere to non-image areas of the plate that are receptive to water. only the inked image portion of the plate is transferred to a rubber blanket cylinder, which transfers the image to the substrate being used.

stage 1: preparation of the dishes

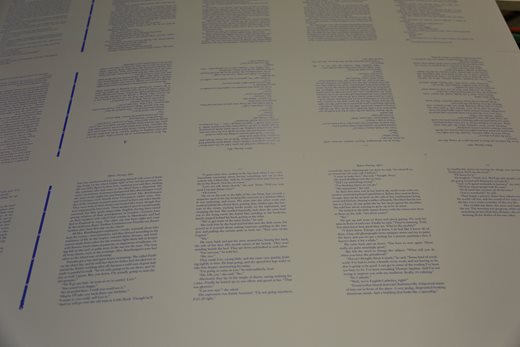

Before printing can take place, the book’s metal printing plates must be prepared. the rubber is burned into each plate, leaving an image of text from the book.

You are reading: How are books printed

Originally, text was made up of individual pieces of metal type assembled page by page, rather than being laser etched onto a plate digitally, an immensely skillful and painstaking process. Advances in printing technology to what we have today have enabled the production of affordable, mass-market books and revolutionized the spread of knowledge and art.

.jpg)

Every printing press has its own specifications that determine how many pages can be produced on a single plate: it’s usually sixteen, but it can be eight, thirty-two, etc. The number of pages must be a multiple of this figure, which is why you’ll sometimes see blank pages at the beginning or end of books. A 1000 page book, for example, can be broken down into sixty-three sixteen page sections with eight blank pages.

Stage 2: Printing the book

A roll of paper is loaded onto the roll stand of the printing press. paper type, weight, color, and width differ from book to book, and are specified and supplied by the publisher. the reel stand is designed to unwind paper rolls on printing lines.

The paper then passes through a chain of rollers, which is called the “feed” station. The main function of the feed station is to act as a reel stand driver, pulling paper from the running reel at the same speed as the running press. it also helps prevent wrinkling and keeps the paper straight as you go.

See Also: 6 Dr. Seuss books will no longer be published due to racist images | Article | Kids News

After the in-feed, the running paper reel enters the print units, passing through the inking system, the damping system and the print cylinders. First, the rollers in the inking system transfer ink onto the metal plate. Then the rollers in the damping system spray water onto the plate removing all excess ink from areas that do not need ink. Finally, the print cylinders transfer the inked image area onto a cylinder which then pastes the image onto the paper reel.

null

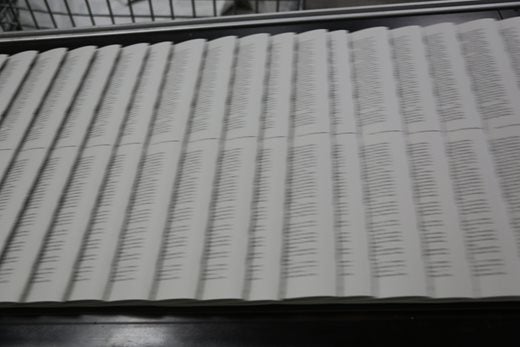

after the paper roll has passed through the printing unit, it will be cut:

null

folded, stacked and bundled, ready to be bound and bound.

Did you know that a book is printed in sections? Each section has a unique barcode printed on it that will be used when the book is bound and cased with the cover, and is cut off in the final stages.

stage 3: book cover preparation

See Also: The 7 Best Textbooks for Medical Students (2022 Edition)

Book covers are printed on a separate printer as they require specialized printing, which can be colored foil or embossing, for example.

Usually two book covers are printed on one sheet of paper. they are cut to size and trimmed.

For hardback jackets, cardboard and endpapers are pasted to the covers before the jacket is added to the book.

stage 4: add the cover to the book

Since the book is printed in sections, the sections must be stacked correctly (using the barcodes we mentioned) before the cover is glued on.

phase 5: the book!

After gluing the book cover to the printed sections of the book, it is trimmed one last time. And there you have it: the book is printed and ready to be published.

butcher boy fresh off the press! #classic chopper

null

all photos © maya robert.

See Also: Halo novels – Halopedia, the Halo wiki